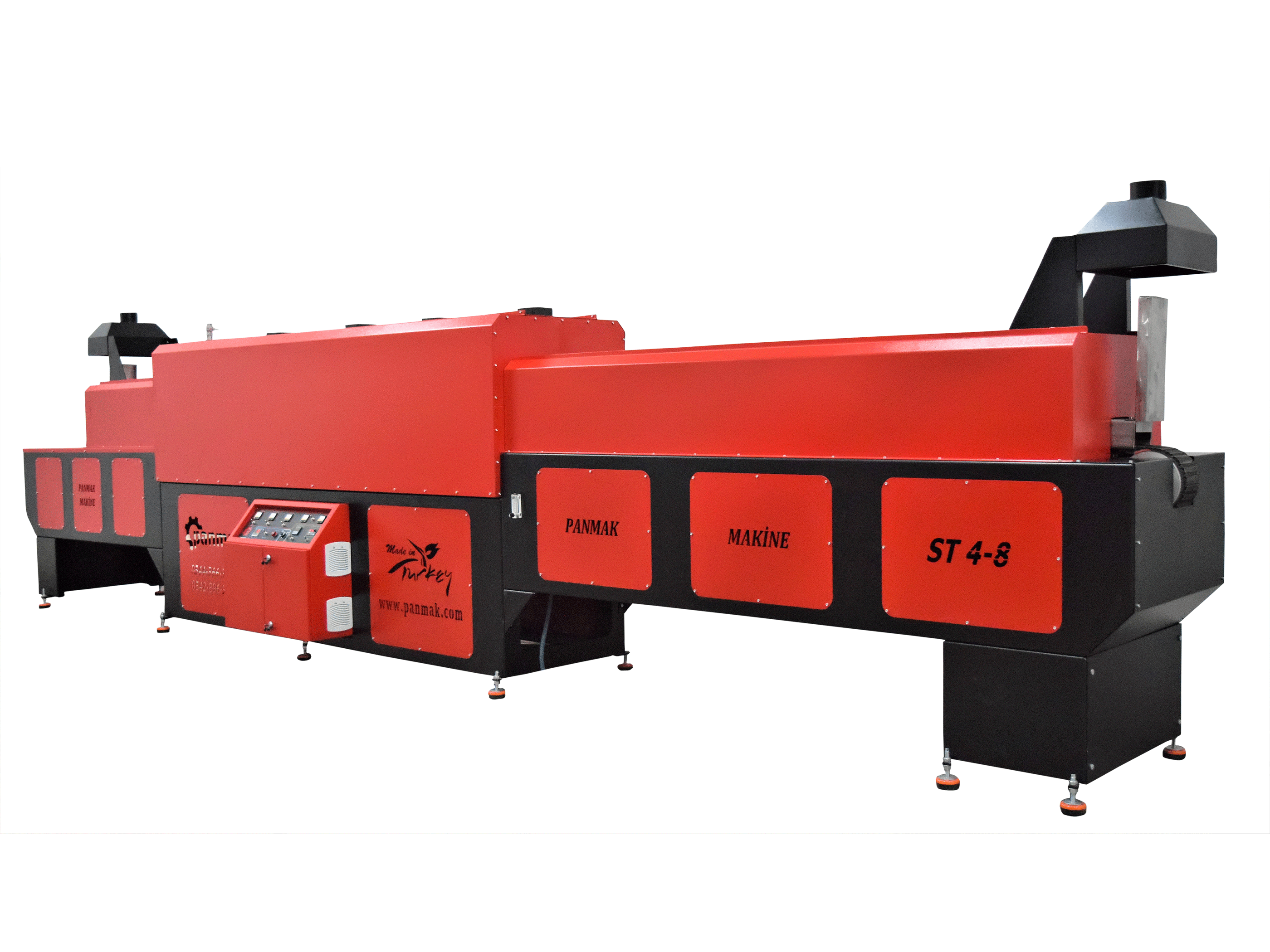

Sinter Conveyor Furnace, Sinter Belt Conveyor Furnace

Sinter Conveyor Furnace, Sinter Belt Conveyor Furnace

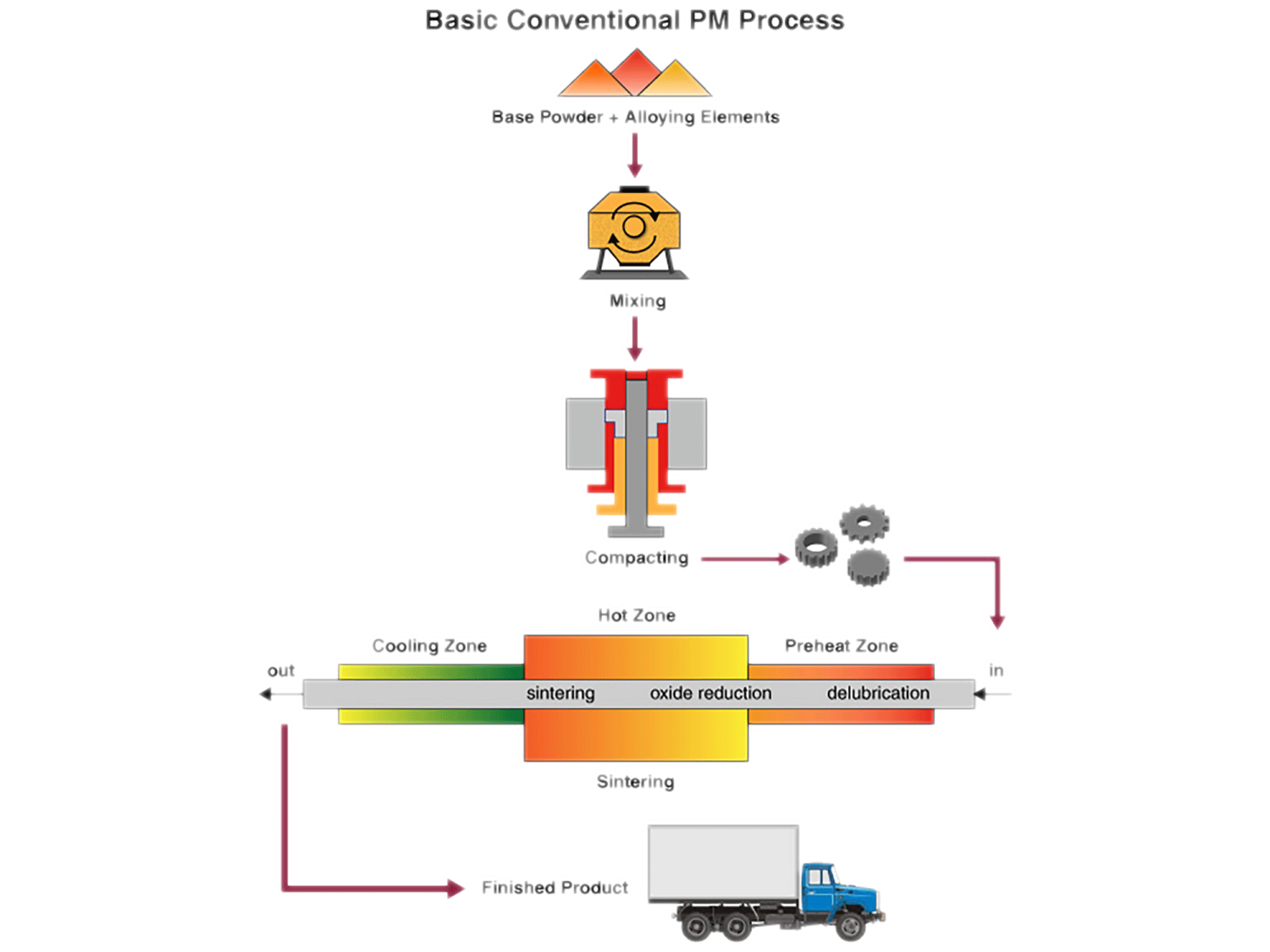

Panmak Sinter Belt Furnace is an industrial type electrically heated sintering furnace. After the sinter belt furnace powder metal mixture is compressed by cold press method, it is ensured that it is turned into final product from heat processes. It is used in the manufacture of beads for diamond wires, sectors for diamond tools and free sintering of powders for brazing.

Advantages

High sintering and soldering speed,

Electric control panel integrated into the oven,

Energy savings up to 50% in electricity consumption,

Constant temperature throughout the inferno,

Inferno made of refractory steel alloy for high operating temperature

Heating and cooling with 3-4 zones as needed.

Deoxidizing gas g(H2 + N2, and NH3)

High efficiency chimneys at the exit of the waste gas

Repeatable work cycles

Features

High precision controllers

Maintaining and saving operating parameters

Control and control of work management as wi-fi connection

throttle control control

Security system check

audible alarms

heat diagrams

Wireless programmer that can connect to smart devices for automatic on/off

Technicial Specifications

Maximum temperature 1150°C

Hell section 150 x 100 & 250 x 120 mm

Usable band width 130 & 225 mm

Conveyor belt speed max 200 mm/min

Heating zones 3 & 4

Heating chamber length 2000, 3000 mm

Oven dimensions cm 600x135x220, 800x135x220

Heating power 36 kW

Electric supply VOLT. 380 50/60Hz - 3ph

Weight 2000 kg